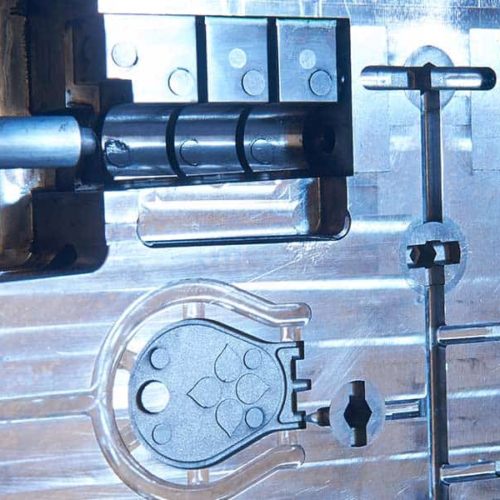

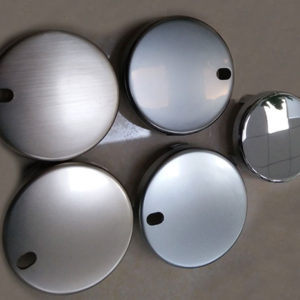

Injection Moulding

We offer competitive, innovative plastic manufacturing solutions for customers of all sizes. As a company we are passionate about what we do, who we work with and we proudly offer services for concept, product engineering and tooling to production.

Whether it is low volume, pre-production, high speed or multi-cavity stack tools, we are able to specify and manufacture the most appropriate options for our customers.

We manufacture using the most cost effective production methods and use a range of state of the art injection moulding machines so that requirements can be met.